Modern robots are fundamentally based on serial communication, which allows the flawless data flow between systems and components. Popular platform in educational and competitive robotics, the VEX V5 system depends on effective serial communication for many operations. We will investigate how to maximize the VEX V5 Serial communication features in this post and discuss how your robotics projects could benefit from them.

Introduction to VEX V5 System

VEX Robotics has transformed the approach of enthusiasts and students toward robotics. Particularly the VEX V5 system is a sophisticated robotics platform combining modern technology with easy programming environments. Handling serial communication is a fundamental feature of the VEX V5 system; this is absolutely essential for jobs including data transport, sensor interface, and microcontroller connectivity.

The foundation of how electronic systems interact is simply serial communication. From orders to sensor data sharing, the VEX V5 Brain runs on this basis.

What is Serial Communication?

Serial communication is the one bit at a time, sequentially, data transfer across a communication channel mechanism. Especially in cases when fast connection is not necessary, this kind of data transfer is simple and quite efficient.

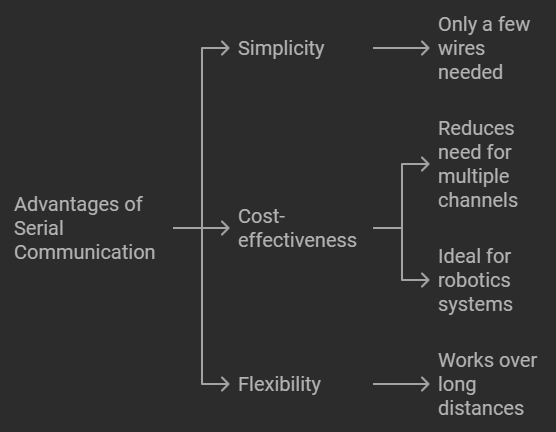

Advantages of Serial Communication:

- Simplicity: Only a few wires are needed to establish communication.

- Cost-effective: It reduces the need for multiple communication channels, making it ideal for robotics systems.

- Flexibility: Serial communication can work over long distances compared to parallel communication.

VEX V5 System and Serial Communication

Built on the reliable microcontroller serving as the core hub for all robot activities, the VEX V5 system is Serial ports let consumers link sensors, peripherals, and even other controllers.

Serial Ports on the VEX V5 Brain

Multiple serial communication ports on the VEX V5 Brain allow for When interacting with outside devices, these ports are absolutely necessary; hence, optimizing their use depends on knowing their setup.

Setting Up Serial Communication on VEX V5

Required Hardware and Software

To begin serial communication with the VEX V5 system, you’ll need the following:

- VEX V5 Brain

- VEX V5 Cables

- VEXcode or PROS for programming

Initial Configuration of VEX V5 Brain

Make sure the VEX V5 Brain is current to the newest firmware before beginning program writing. This guarantees serial communication commands and functionalities are compatible.

Programming for Serial Communication

The VEX V5 system supports two primary programming environments for serial communication:

- VEXcode: An easy-to-use, drag-and-drop programming platform.

- PROS (Purdue Robotics Operating System): A more advanced programming environment that offers greater flexibility for experienced users.

Writing Your First Serial Communication Code

Create a new project first opening VEXcode. Simple commands will be needed to start the serial connection and transmit or receive data.

Common Functions for Serial Communication in VEX V5

VEXcode Functions for Serial Data

VEXcode provides built-in functions for serial communication. Some of the often utilized functions are:

- Brain.Serial.read() – Reads data from the serial port.

- Brain.Serial.write() – Writes data to the serial port.

Using Serial Commands in PROS

For users of PROS, serial communication commands offer more flexibility. Functions like pros::c::serial_read() and pros::c::serial_write() allow for advanced configurations and data handling.

Sending and Receiving Data via Serial on VEX V5

How to Send Data

To send data, use the write() function. For example, if you’re sending sensor readings to another device, the data can be converted into a serial stream and sent over the designated port.

How to Receive Data

The read() function is used to capture incoming data. This is particularly useful when interfacing with external devices like sensors or even another VEX V5 Brain.

Debugging Serial Communication

Make that the baud rate and other settings line up between the sending and receiving equipment. By means of a serial monitor, one can notice possible problems and visualize the transferred data.

Applications of Serial Communication in Robotics

Interfacing with Sensors

Many sensors, such as GPS modules or ultrasonic sensors, use serial communication to send data to the VEX V5 Brain.

Communicating with Other Microcontrollers

If you’re working on a more complex robot with multiple microcontrollers, serial communication is often the go-to method for ensuring they all work in harmony.

Troubleshooting Serial Communication

Common Issues and Fixes

- Mismatched Baud Rates: Ensure both devices share the same baud rate.

- Wiring Errors: Double-check the connections between devices.

Monitoring and Testing Serial Communication

Using a serial monitor in your programming environment allows you to visualize the data being transmitted and received, making it easier to debug any communication issues.

Advanced Topics in VEX V5 Serial Communication

Baud Rate Configuration

Setting the appropriate baud rate is essential for smooth communication. The default baud rate is often 9600, but this can be adjusted for faster data transfer, depending on the devices in use.

Interrupt-Driven Serial Communication

Interrupt-driven communication allows the system to respond immediately to incoming data, ensuring no data is lost during high-speed operations.

Best Practices for Using Serial Communication on VEX V5

Optimizing Performance

Minimizing delays in your code and properly formatting data packets can help you to maximize serial communication and prevent transmission faults.

Ensuring Reliable Data Transfer

Use error-checking mechanisms such as checksums to verify that data has been transmitted correctly.

Integrating Serial Communication with Other Systems

Connecting to External Devices

With serial communication, you can easily connect the VEX V5 Brain to external sensors, GPS modules, or even computers for real-time data logging.

Using Serial to Control Multiple Robots

In competitions, you might need to control multiple robots at once. Serial communication can allow these robots to share data and coordinate their actions.

VEX V5 Serial Communication in Competitions

Reliable communication is quite important in competitive robotics. Serial communication can provide your team a major benefit whether you are managing autonomous activities or guaranteeing real-time data flow.

Real-World Projects Utilizing VEX V5 Serial Communication

Case Study: Serial Communication in Autonomous Robots

In a recent VEX Robotics competition, one team used serial communication to interface with a GPS sensor, allowing their robot to navigate the field autonomously.

Conclusion

An essential part of the VEX V5 system, serial communication helps robots to be more functional by means of data transfer between equipment. Whether your robotics projects call for sophisticated multi-robot systems or basic sensor data transfer, knowing serial communication is crucial to advancing your work.

FAQs

- What is the default baud rate for VEX V5 serial communication? The default baud rate is typically set at 9600, but it can be adjusted based on your project requirements.

- Can I use a different software for programming VEX V5 serial communication? Yes, aside from VEXcode, you can use PROS for more advanced serial communication setups.

- How do I debug serial communication issues in VEXcode? Use the built-in serial monitor and ensure that both ends of the communication have matching settings like baud rate.

- How can I optimize the speed of data transfer in serial communication? You can increase the baud rate or use more efficient data packet structures to enhance transfer speed.

Can I use VEX V5 to communicate with external microcontrollers like Arduino? Yes, VEX V5 can communicate with other microcontrollers via serial communication, provided the wiring and baud rates are configured correctly.