Since VEX Robotics provides students with practical knowledge in constructing, programming, and problem-solving, it has grown to be a necessary component of STEM education. Particularly the most recent in VEX technology, the VEX V5 platform boasts strong programming choices, clever sensors, and powerful motors. Perfect for contests, it inspires students to approach problems like engineers. The four-bar linkage is among VEX Robotics’ basic systems. But why is a vex v5 four bar connection so popular and exactly what is it?

What is a Four-Bar Linkage?

Made of four links joined by pivots, a four-bar linkage is a basic mechanical system allowing movement in specified directions. It’s known as a “four-bar” since it employs four connected elements forming a closed chain, usually producing smooth, repeating motion courses. This basic mechanism makes difficult jobs possible, so it is a mainstay in robotics for lifting and stretching motions.

The Purpose of Four-Bar Linkages in Robotics

Four-bar links are perfect for arms, claws, and other extensions in robotics since they enable controlled movement over set ranges. Especially helpful for gripping and lifting, their consistent motion path guarantees that the end effector—the part touching or interacting with the environment—remains parallel to a given orientation.

Components Needed for a VEX V5 Four-Bar Linkage

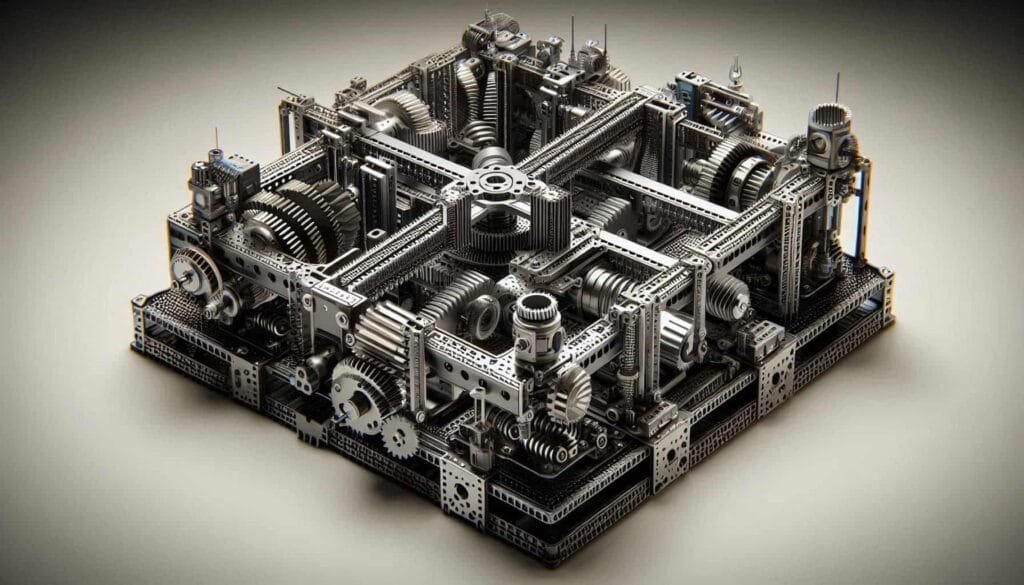

To build a four-bar linkage with VEX V5, you’ll need the following components:

- VEX V5 Structural Parts: metal or plastic bars and beams for the frame.

- V5 Motors: for powering the movement.

- Gears: to create torque and smooth motion.

- Axles and Bearings: for stability and rotation.

- Fasteners and Tools: such as screws, nuts, and wrenches to assemble.

Types of Four-Bar Linkages in VEX Robotics

VEX users commonly use two main types of four-bar linkages:

- Parallel Four-Bar: Keeps the top bar parallel to the base, allowing linear movement.

- Non-Parallel Four-Bar: Has angled connections, creating more complex paths but allowing versatility.

Building a Four-Bar Linkage with VEX V5

Start with a clear blueprint, as alignment is critical in four-bar systems. Here’s a basic build process:

- Assemble the Frame: Attach two structural beams as the base.

- Create Parallel Bars: Attach two bars (these will lift) to the base.

- Add Motor and Gears: Place a motor to control the movement and gears to adjust speed and torque.

- Link and Test: Connect all parts and run an initial test to ensure stability.

Programming the VEX V5 Four-Bar with VEXcode

Programming the vex v5 four bar mechanism comes second after construction is under way. The proprietary programming tool VEXcode makes motor control simple. Setting motor speed, direction, and restrictions on movement is part of basic programming so that the four-bar linkage retracts without jamming and extends smoothly.

Adjusting the Range of Motion in Four-Bar Linkages

A four-bar linkage depends critically on range of motion. Link lengths or motor speed in VEXcode allow you to modify the motion. A precise configuration lets your mechanism expand completely without stressing the motor or running afoul of other parts.

Mechanical Advantages and Efficiency of Four-Bar Linkages

A four-bar linkage offers a mechanical advantage in mechanics, therefore facilitating lifting or pushing. Experimenting with gear ratios will help you to discover the perfect combination of power and speed, so guaranteeing efficiency for school projects as well as for competition.

Testing and Troubleshooting Your VEX V5 Four-Bar Mechanism

Testing is crucial for ensuring that the four-bar linkage works as expected. Common issues include:

- Alignment Problems: If bars are misaligned, movement will be restricted.

- Motor Overload: An overloaded motor can overheat; adjust the speed or torque settings if necessary.

- Slipping Gears: Tighten any loose gears to prevent slipping.

Applications of Four-Bar Linkages in VEX Competitions

Four-bar connections excel in VEX events when accuracy lifting and placing call for it. These systems are used by several teams for object lifting, game element manipulation, and interaction with barriers particular to their competitiveness. Teams gain scoring advantage from their dependability and fluid motion.

Tips for Improving Four-Bar Performance

By adding rubber bands to a four-bar linkage, one may counteract gravity and ease motor strain. Additionally important is weight control; a smaller linkage goes faster and uses less power, therefore improving the agility of your robot.

Maintaining Your Four-Bar Linkage Mechanism

Your VEX four-bar linkage’s lifetime is extended by regular maintenance. Lubricate moving parts; look for loose connections; replace any worn-out components. This maintains dependability and flawless operation of the system.

Real-World Applications of Four-Bar Linkages

From automotive suspensions to aerospace equipment, four-bar links abound in actual gear. These uses demonstrate the dependability and adaptability of four-bar links, therefore motivating students to approach engineering problems creatively.

Conclusion

For those who enjoy VEX Robotics, four-bar connections present an amazing chance to investigate fundamental mechanics while completing challenging projects. Understanding the ideas behind these systems helps students build more competitive, useful, and efficient robots. Key is experimentation and testing; so, do not hesitate to change and improve your designs to attain optimal performance.

FAQs

- What is the main benefit of a four-bar linkage in VEX Robotics?

- It provides a smooth and repeatable movement, making it ideal for tasks that require stability and precision.

- Can I use multiple four-bar linkages on a single VEX robot?

- Yes, you can combine multiple linkages to handle complex tasks or create unique motion paths.

- How do I prevent my four-bar linkage from getting stuck?

- Ensure proper alignment and regularly check for loose screws or worn-out components.

- What coding software is best for controlling VEX four-bar linkages?

- VEXcode is the primary software, offering intuitive tools for programming VEX V5 robots.

- Can a four-bar linkage lift heavy objects in VEX competitions?

- Yes, but it depends on the gear ratio, motor strength, and overall design balance