Mecanum vs omni wheels are designed to offer multidirectional movement, therefore enabling vehicles to negotiate confined areas and perform difficult maneuvers. Though their goal is the same, the mechanics and technology underlying them differ somewhat greatly. Knowing these variances will enable you to select the appropriate wheel type for your particular requirements.

2. What are Mecanum Wheels?

2.1 Design Features

Mecanum wheels have a distinctive construction whereby rollers are positioned around the wheel’s circumference at a 45-degree angle. These rollers translate rotational movement into lateral movement therefore enabling the wheel to move in several directions.

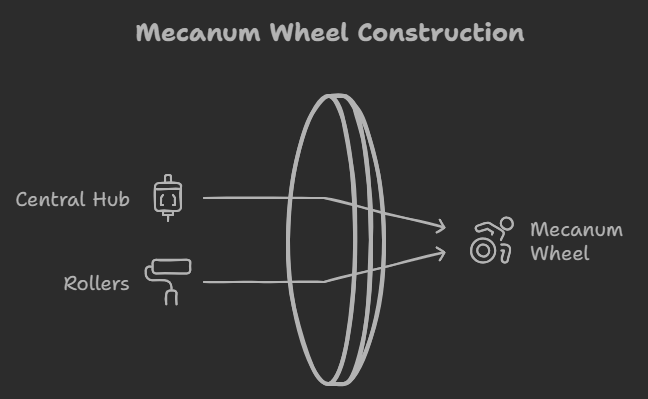

The typical construction of a Mecanum wheel includes:

- Central Hub: The main part that attaches to the motor.

- Rollers: These are angled and mounted on the wheel’s outer surface, allowing for lateral movement.

- Tread: The wheel’s outer material that provides traction.

2.2 How Mecanum Wheels Work

Mecanum wheels run on independently regulating each wheel’s direction and speed. The car can forward, backwards, sideways, or rotate in position by changing the speed and wheel rotation. Applications where space is limited, such those involving robotics contests or warehouses, depend on this capacity.

3. What are Omni Wheels?

3.1 Design Features

Though they have different construction, Omni wheels also let for multidirectional movement. A conventional wheel with smaller rollers—or casters—around its circle is an omni wheel. These free rotating rollers let the wheel glide sideways.

Key components of omni wheels include:

- Central Hub: Similar to Mecanum wheels, the hub connects to the motor.

- Rollers: Smaller than those on Mecanum wheels, these are aligned perpendicular to the wheel’s rotation.

- Tread: The contact surface for traction.

3.2 How Omni Wheels Work

By means of the rollers, Omni wheels achieve lateral movement and thereby minimize friction. The smaller rollers let one move sideways when the main wheel revolves. Like Mecanum wheels, omni wheels move efficiently only with individual control of every wheel.

4. Comparative Analysis of Mecanum and Omni Wheels

4.1 Maneuverability

Though their approaches are different, mecanum vs omni wheels offer great maneuverability. Excellent agility in confined areas is provided by mecanum wheels’ diagonally moving action. On the other hand, omni wheels are ideal for particular jobs since they shine in basic lateral movements.

4.2 Speed and Efficiency

Mecanum wheels’ angle of the rollers causes some loss in speed when performing complicated motions. When negotiating limited spaces, nevertheless, they can be rather effective. Omni wheels are more effective for jobs needing quick transitions since they usually keep better speeds throughout lateral motion.

4.3 Load Capacity

Depending on their construction materials and size, these wheel kinds have rather different load capability. Generally speaking, Mecanum wheels’ strong construction results in a greater load capacity. Under severe loads, especially during lateral motions, Omni wheels could find difficulty since the friction of the smaller rollers can create a restricting element.

4.4 Complexity and Control

To handle its multidirectional capacity, Mecanum wheels sometimes call for more sophisticated control algorithms. For operators, this intricacy could cause a more sharp learning curve. On the other hand, omni wheels are more easily controlled and so more accessible for novices and in situations where quick deployment is crucial.

5. Applications of Mecanum Wheels

Mecanum wheels are widely used in applications where agility and maneuverability are paramount. Some common applications include:

- Robotic Competitions: Many robotics teams utilize Mecanum wheels for their ability to navigate complex arenas.

- Warehouse Automation: Mecanum wheeled robots are prevalent in warehouse settings for transporting goods efficiently.

- Medical Equipment: Certain medical carts employ Mecanum wheels to navigate tight hospital corridors.

6. Applications of Omni Wheels

Omni wheels are utilized in various applications where lateral movement is advantageous. Some typical use cases include:

- Automated Guided Vehicles (AGVs): Omni wheels help AGVs maneuver in tight spaces within manufacturing facilities.

- Mobile Platforms: Omni wheels are often found on mobile robot platforms for easy navigation in crowded environments.

- Robotic Arms: Some robotic arms use omni wheels to achieve precise positioning and movement.

7. Advantages and Disadvantages of Mecanum Wheels

Advantages

- Superior Maneuverability: Excellent for navigating tight spaces.

- Multidirectional Movement: Can move diagonally and rotate in place.

- High Load Capacity: Typically designed to carry more weight.

Disadvantages

- Complex Control: Requires advanced programming for optimal performance.

- Speed Limitations: May be slower when executing certain movements.

- Surface Sensitivity: Performance can be affected by uneven surfaces.

8. Advantages and Disadvantages of Omni Wheels

Advantages

- Simplicity: Easier to control and program than Mecanum wheels.

- Higher Speed: Maintains speed during lateral movement effectively.

- Versatility: Useful in a variety of applications.

Disadvantages

- Lower Load Capacity: May struggle with heavy loads during lateral movement.

- Limited Diagonal Movement: Not as agile as Mecanum wheels for complex navigation.

- Increased Friction: Smaller rollers can cause friction issues under heavy loads.

9. Conclusion

All things considered, Mecanum and omni wheels have special benefits fit for various uses. While omni wheels shine in applications where speed and simplicity are critical, mecanum wheels are ideal for circumstances needing complex motions and greater load capabilities.

The particular requirements of your project will ultimately determine which of Mecanum’s or omni wheels you need. Carefully weighing the benefits and drawbacks of every wheel type will help you to decide which one will improve the performance of your mobile or robotic platform.

10. FAQs

1. Can Mecanum wheels operate on all surfaces?

While Mecanum wheels can handle various surfaces, their performance may diminish on rough or uneven terrain due to their design.

2. Are omni wheels suitable for outdoor use?

Yes, omni wheels can be used outdoors, but their effectiveness may depend on the surface conditions and load requirements.

3. How do I control Mecanum wheels?

Mecanum wheels require programming for each wheel’s motor to achieve the desired movements, often using specialized control algorithms.

4. Can I use Mecanum wheels on a robot designed for omni wheels?

You can adapt a robot designed for omni wheels to use Mecanum wheels, but it will require modifications in control systems and possibly structural changes.

5. Which wheel type is better for high-speed applications?

Omni wheels are generally better for high-speed applications due to their design, which allows for faster lateral movements.