Stored compressed air in a pneumatic tank is then released to operate different parts of a VEX robot, including pistons or other air-powered machinery. The fill air in pneumatic tank vex v5 system stores the compressed air necessary to run these actuators, enabling reproducible and under control motions. Usually composed of metal or plastic, the tank has a pressure gauge to track internal air pressure.

Why Use Pneumatics in VEX V5 Robots?

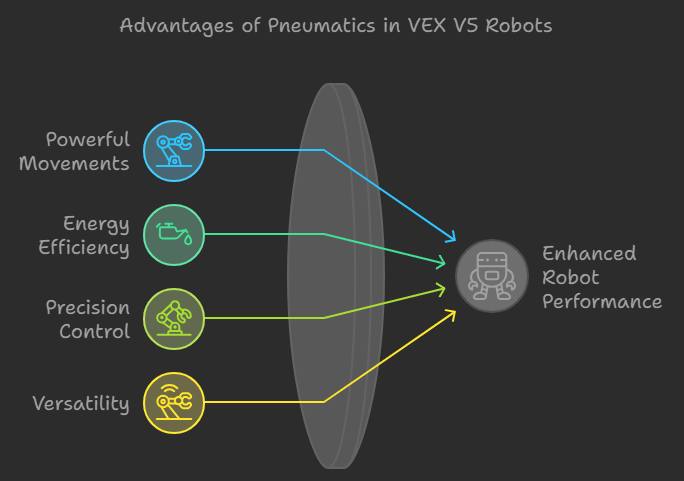

Pneumatics offers several advantages for VEX V5 robots:

- Powerful Movements: Pneumatic systems can generate large amounts of force in a short time, making them ideal for tasks requiring quick and strong movements.

- Energy Efficiency: Once filled, the air in the tank can be used multiple times before needing to be refilled, conserving energy.

- Precision Control: Pneumatic systems allow for fine-tuned control over movement, making them excellent for tasks that require precision.

- Versatility: Pneumatics can be used in various applications, from lifting arms to gripping objects.

Components of a VEX V5 Pneumatics System

Before you start filling your pneumatic tank, it’s essential to understand the main components of a VEX V5 pneumatic system:

- Pneumatic Tank: Stores the compressed air.

- Air Compressor: Fills the tank with compressed air.

- Pressure Gauge: Measures the air pressure inside the tank.

- Solenoids: Valves that control the release of air.

- Pneumatic Tubing: Channels the air from the tank to the pistons or actuators.

- Pneumatic Cylinders (Pistons): Convert the compressed air into mechanical motion.

Tools and Equipment Required for Filling the Pneumatic Tank

To fill air in pneumatic tank vex v5 robot, you will need the following tools and equipment:

- Air Compressor: A small, portable compressor is ideal for this task.

- Pressure Gauge: This ensures you do not overfill the tank.

- Fill Valve: Used to connect the compressor to the pneumatic tank.

- Tubing: To channel air from the compressor into the tank.

- Safety Goggles: Always recommended when dealing with pressurized systems.

Safety Considerations When Working with Pneumatics

Safety is critical when working with compressed air.Here are some safety suggestions to bear in mind:

- Do not overfill the tank. Exceeding the recommended pressure can cause the tank to rupture, potentially leading to injury or damage.

- Wear safety goggles to protect your eyes from any accidental release of pressurized air.

- Regularly check the pressure gauge to ensure it stays within safe operating limits.

- Inspect all components for leaks or damage before filling the tank.

Step-by-Step Guide to Filling a Pneumatic Tank

A. Preparation

Make sure your robot’s pneumatic system is correctly constructed and that damage or leaks are not evident before you start. Make sure the pneumatic tank rests on a steady surface and that every link is tight.

B. Checking the Pressure Gauge

Check the pressure gauge to find the tank’s current air pressure level prior to filling. Typically, VEX V5 pneumatic systems run best at about 100 psi ( pounds per square inch).

C. Attaching the Fill Valve

Attach the pneumatic tank’s fill valve. Make sure the valve is well fastened to stop any air from leaking during filling.

D. Using an Air Compressor

Clip the air compressor to the fill valve. Start air filling the tank by turning on the compressor. As the air is being forced into the tank, monitor the pressure gauge.

E. Monitoring the Pressure

It’s imperative to keep constant eye on the pressure gauge while filling the tank. Usually, VEX pneumatic systems should run with a maximum pressure of about 100 psi. Damage or safety risks can result from overfilling the tank beyond this pressure.

F. Disconnecting the Compressor

Turn off the air compressor and gently separate it from the fill valve once the intended pressure is attained. Closing the fill valve will help to stop air from leaving the tank..

Optimal Pressure Levels for VEX V5 Pneumatics

Usually, a VEX V5 pneumatic tank should have optimal pressure between 80 and 100 psi. For most jobs, this level offers enough force without taxing the system excessively. While over 100 psi raises the danger of system failure, operating below 80 psi can lower the effectiveness of your pneumatic system.

Common Mistakes to Avoid When Filling the Tank

- Overfilling the Tank: Exceeding the recommended pressure can damage the tank or other components.

- Using a Faulty Pressure Gauge: An inaccurate gauge can lead to over- or under-filling.

- Not Checking for Leaks: Always inspect your system for leaks before and after filling the tank.

Testing the Pneumatic System After Filling

Testing the pneumatic system by running the solenoids and pistons is absolutely vital once the tank has been filled. This guarantees that the system is operating as it should and that leaks are absent.

Maintaining Your VEX V5 Pneumatics System

Your pneumatic system’s lifetime will be extended and dependable performance guaranteed by regular maintenance. Important chores for upkeep consist in:

- Inspecting hoses and tubing for wear or leaks.

- Checking pressure gauges to ensure accuracy.

- Cleaning solenoids and valves to prevent dirt buildup.

Troubleshooting Pneumatic Issues

If your pneumatic system is not working as expected, some common issues to check for include:

- Leaks: Air escaping from tubing or connections.

- Low Pressure: The tank may not be filled to the correct pressure level.

- Faulty Solenoids: Check if the solenoids are properly controlling the air flow.

How to Store a Pneumatic Tank Properly

Store your pneumatic tank cool, dry when not in use. To avoid long-term harm, make sure the tank is empty before storage.

Advanced Pneumatic Techniques for VEX Robotics

Pneumatics allow sophisticated users to create bespoke actuuations and multi-stage movements. For long pneumatic activities during contests, you can even mix many tanks.

Conclusion

Although filling a pneumatic tank in a VEX V5 robot is easy, it is imperative to observe correct safety and operating policies. Pneumatics will help your robot to be much more competitive and functional. Just keep the system under regular maintenance and steer clear of common errors include overfilling or disregarding leaks.

FAQs

- How do I know when my pneumatic tank is full?

You can monitor the pressure using a pressure gauge. For VEX systems, the tank should typically be filled to around 100 psi. - Can I overfill the pneumatic tank?

Yes, overfilling can damage the tank and pose a safety hazard. Always monitor the pressure gauge to avoid exceeding the recommended pressure. - Why is my pneumatic system losing pressure quickly?

This could be due to a leak in the tubing or a loose connection. Inspect all components and tighten any loose fittings. - What is the best pressure for VEX pneumatics?

The optimal pressure range is between 80 and 100 psi for most applications.

How often should I refill the pneumatic tank?

It depends on usage, but you should refill the tank whenever the pressure drops below the optimal range for your system.